Description

4 Component heavy duty PU floor coating / PU paint / Industrial PU flooring in Bangladesh

Key Features of Ducon’s Industrial PU Flooring :

- Seamless Elegance: Ducon’s PU floor creates a seamless surface that not only enhances the visual appeal of industrial spaces but also minimizes the risk of cracks and joints, reducing the potential for dirt accumulation and ensuring a hygienic environment.

- Exceptional Durability: Industrial environments demand robust flooring solutions. Ducon’s PU paint in Bangladesh is engineered to withstand heavy foot traffic, impact, and exposure to chemicals, providing a long-lasting flooring system.

- Chemical Resistance: PU flooring is designed to resist a wide range of chemicals commonly found in industrial settings. This feature ensures that the flooring remains unharmed, maintaining both its appearance and functionality.

- Cost-Effective Solution: Ducon understands the importance of cost-effective PU flooring in Bangladesh. Our PU coating offers an optimal balance between performance and affordability, providing value for every investment.

Why Choose Ducon for PU Flooring in Bangladesh?

- Expertise: With a legacy of seven years in the construction chemical industry, Ducon brings unparalleled expertise to every project. Our seasoned professionals understand the unique challenges of the Bangladeshi industrial sector, offering tailored solutions that align with specific requirements.

- Innovation: Our Industrial PU coating reflects our commitment to staying ahead of industry trends. We continually invest in research and development to integrate the latest advancements into our PU flooring solutions, ensuring optimal performance.

- Best Pricing: Ducon believes in transparency, and our pricing reflects our commitment to delivering value. Contact us for a quote, and discover the affordability of our top-tier PU paint in bangladesh.

- Tailored Solutions: Our PU Flooring solutions are customizable to meet the specific needs of each usage area.

Recommended use of PU Flooring:

- Pharmaceuticals and Laboratories

- Educational Institutions

- sports and fitness arenas (Gym)

- Hotels, resorts, and restaurants

- Retail stores, showrooms, and shopping malls

- Textile & any kind of Industries

- Food processing & Beverages

- Hospitals & Warehouses

- Residential spaces, kitchens, living areas

- Any kind of heavy-duty load areas

Transform Your Space with Ducon’s Industrial PU Flooring:

Whether you’re seeking a flooring solution for manufacturing facilities, warehouses, or commercial spaces, Ducon’s Industrial PU Flooring in Bangladesh stands as a testament to quality and reliability. Contact us today to explore how our PU flooring can elevate your space, providing a foundation of excellence that lasts.

Materials Consumption:

Application of PU Flooring:

Please note our general processing guidelines for DUCON systems. DUCON systems should only be processed by trained personnel.

Surface Preparation:

The concrete substrate shall be firm, clean, and dry with a surface pull-off strength of a minimum of 1.5 N/mm². The substrate quality should be a monolithic reinforced concrete with min. C25/30 according to EN 206-1, (except light-weight concrete), or cement screeds in the composite, minimum CT-C30-F4, minimum layer thickness 25 mm, for other substrates see our general application guidelines for DUCRETE concrete systems.

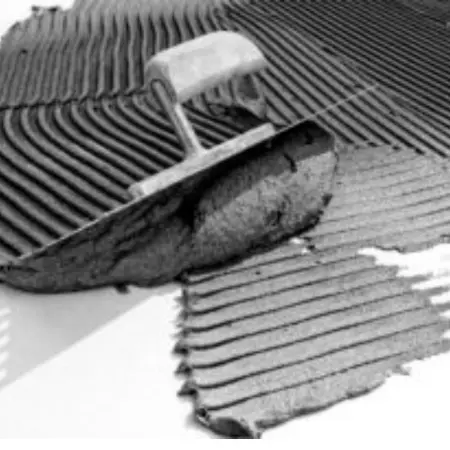

Pu floor (DUCRETE MF) is always applied on a prepared surface. Remove surface laitance, contaminants, coating, curing compound, and all weak and loose materials. Prepare concrete surface by diamond grinding, scarifying, or captive shot blasting to provide the appropriate surface profile for optimum mechanical keying. Cut grooves of 3 mm width and 5 mm depth minimum just inside the perimeter of the area and around drains, columns, and protrusions.

Self-Levelling Coating / Wear Coat:

Apply the self-leveling coat DUCRETE MF with a notched trowel or spatula or with a notched squeegee in the required layer thickness onto the primed surface. The entrapped air must be de-aerated with a spike roller. The consumption is approx. 5.7–7.6 kg/m² depending on the required layer thickness.

After curing remove not bound QS by sweeping and vacuum cleaning. If low slip resistance is required grind the surface slightly before vacuum cleaning.

Pu flooring Procedure:

Before starting the application, the material temperature must be close to the site conditions but should have min. 10°C.Dispense the color paste into Component A. Mix to disperse the color paste (1 minute) until homogeneous, add component B and mix (1.5 to 2 minutes) until homogeneous using an electric stirrer with a speed of min. 300 rpm.

Over Coating:

Overcoating should be carried out within 24 hours after application of DUCRETE MF. If longer than 24 hours, it is necessary to lightly grind the surface before the over-flooring coating is carried out.

Color of PU Flooring:

Green, Oxide-Yellow, Red, Grey, Beige, Cream, Grey-Brown and More

Packaging:

DUCRETE MF is available in 20 Kg (Appx.) formulated ready-to-use mixture component pack

Reviews

There are no reviews yet.