Description

3 Component self leveling, solvent free epoxy flooring, colored epoxy coating / floor epoxy paint in bangladesh

Benefits of Epoxy Floor Coating:

- Chemical Resistant– epoxy paint resists dilute acids and alkalis, aliphatic solvents, and commercial cleaning agents Abrasion/impact resistant – hard wearing and durable

- Resistance to Moisture and Humidity – Epoxy flooring creates a moisture-resistant barrier, preventing water and humidity from penetrating the substrate

- Durability – Epoxy floor coatings create a tough and durable surface that can withstand heavy traffic, impact, and abrasion.

- Versatility – Epoxy paint can be applied to various surfaces, including concrete, metal, and wood

- Highly Compacted– high compressive strength, 100 MPa

- Machine Application– Epoxy flooring coating is easy to install, consistent flat surface finish, and no trowel marks

- Excellent Adhesion– to concrete and most other coating or topping systems

- Self-Sealing– impervious surface finish without further seal coats.

- Homogeneous– uniform color through the depth of the product

- Scratch Resistant– minimize the effects of scratch marks

- Longevity- Floor epoxy paint can have a long service life

- Solvent Free– non-flammable, no fire hazard

- Low / No Odour– does not taint food

Recommended Use:

- Medium duty Industries

- Pharmaceuticals & Hospitals

- Schools & Offices

- Exhibition Centers

- Laboratories

- Dry process area

- Clean rooms and walls

Why Choose Ducon for Epoxy Flooring in Bangladesh?

- Experience: With seven years of expertise in the construction chemical industry, Ducon brings a wealth of experience to every project. Our team of experts understands the unique challenges of epoxy paint in Bangladesh industrial landscape, providing tailored solutions that address specific needs.

- Innovation: Ducon is committed to staying at the forefront of innovation. Our epoxy floor coating is a result of continuous research and development, incorporating the latest advancements in epoxy technology to deliver superior performance.

- Local Presence: As a Bangladesh-based company, Ducon understands the local market intimately. Our strategically located facilities ensure timely delivery and responsive customer support, setting us apart in the industry and making us the best-service epoxy flooring in Bangladesh.

Materials Consumption:

2.2 kg/m2 per Millimeter Thickness

Application of Epoxy Flooring:

Substrate Preparation:

The substrate must be firm, clean, dry and have a tensile strength of 1.5 N/mm² minimum. Wet areas shall be dried with a blow torch. The moisture content in the substrate must not exceed 4 CM%. New concrete must be allowed to cure for a minimum of 28 days. Repair imperfections (holes and cracks) with an epoxy patching compound such as DUPOXY SL where necessary. Remove surface laitance, contaminants, coating, curing compound, and all weak and loose materials. Prepare substrate by Captive Shot Blasting. Rough contaminations can be removed by grinding.

Primer:

Apply an epoxy floor coating such as DUPRIME 200 by roller to the prepared surface. If the surface is porous, a second coat of primer may be necessary. To improve inter-layer adhesion, sprinkle 0.2-0.5 mm quartz sand lightly (approx. 600 g/m²) while the primer is still wet. The mortar coating must be applied within 24 hours after the primer has been laid.

Procedure:

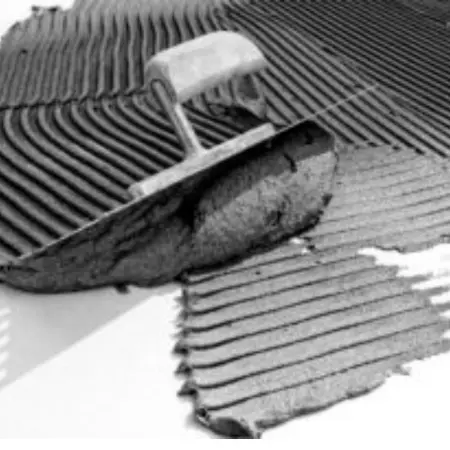

Before starting the application, the material temperature must be close to site conditions. Empty the content of component B (Hardener) into component A (Base Resin). Mix with a suitable mixer at a speed of 500 rpm to avoid incorporating excessive air into the mix. Mix for 2 minutes. Transfer the mixture to another clean container and mix for 1 minute. Component C is premixed dry in a forced action pan mixer. Afterward, the mixed binder is added and mixed with Component C for a minimum of 3 minutes. The mortar is applied onto the primed surface at a minimum layer thickness of 7-9 mm using a screed box, pin rake, or hand trowel and finished off by hand or specially designed ‘helicopter’(refer DUCON). After the mortar has cured, the surface is self-sealing and hence there is no need for any further sealing.

Color of Epoxy Flooring:

Dupoxy Standard Colors (Customizable)

Packaging:

- DUPOXY SL is available in 20 kg bags (Parts A, B, C, D)

Reviews

There are no reviews yet.